Welcome to fabheavyparts.com, where we strive to simplify the daunting task of purchasing a fuel pump for your engine. Our mission is to make the process easy and painless for you. In this comprehensive Buyer's Guide, we aim to address any questions you may have during your search for the perfect fuel pump for your vehicle.

What is a fuel pump?

Let's start by understanding what a fuel pump is and its crucial role in your vehicle. The primary function of a fuel pump is to transfer fuel from the fuel tank or reservoir into your engine. In modern vehicles, the fuel pump is typically part of a complete fuel pump assembly, which includes the sending unit, level arm, and fuel filter. It's important to note that different types of fuel pumps exist to cater to various engine configurations and fuel delivery systems. Let's explore these types in detail:

1. Mechanical Fuel Pump:

- Found in older vehicles that use a carburetor to deliver fuel into the engine.

- Located inside the engine bay.

- Not commonly found in newer engines.

2. Electric Fuel Pump:

- The most prevalent type of fuel pump in modern vehicles.

- Electric fuel pumps are submerged inside the fuel tank and work in conjunction with the fuel injectors.

- Typically operates at a higher pressure (around 30-40 psi) compared to mechanical fuel pumps.

- Offers improved performance and efficiency.

3. Direct Injection Fuel Pump:

- Specifically designed for direct injection vehicles.

- Combines elements of mechanical and electric fuel pumps.

- Located inside the engine bay and mechanically driven by the camshaft, oil pump, or vacuum pump.

- Works alongside an in-tank electric fuel pump.

- Increases fuel pressure to approximately 2000-3000 psi.

- Sprays fuel directly into the combustion chamber for enhanced efficiency.

How Does a Fuel Pump Work?

The fuel pump plays a crucial role in the functioning of a vehicle by efficiently delivering fuel from the tank to the engine. Utilizing an electric-powered motor, the fuel pump is typically housed within the vehicle's tank. Comprised of an intricate system of valves and springs, it works harmoniously to create suction, facilitating the movement of fuel.

When the fuel pump is activated, it initiates a suction process that draws fuel from the tank. This is made possible by the coordinated action of the valves and springs within the pump. As fuel is drawn into the pump, the return spring exerts pressure, propelling the fuel up into the fuel lines. This creates the necessary pressure for a smooth and consistent flow of fuel to the engine.

It is important to note that the fuel pressure within the lines is not directly regulated by the pump itself. Instead, the pump operates at its maximum capacity based on the voltage supplied by the vehicle. The fuel pressure is subsequently regulated downstream at the engine by a component known as the fuel pressure regulator (FPR). The FPR ensures that the fuel pressure remains within the optimal range for efficient engine performance.

In most cases, a fuel pump is part of a larger assembly that includes additional components such as a sending unit, level arm, and screen filter. This comprehensive assembly ensures the accurate measurement of fuel levels, facilitates the smooth operation of the fuel pump, and provides filtration to prevent contaminants from reaching the engine.

By understanding the intricate workings of a fuel pump, drivers can appreciate the vital role it plays in maintaining the optimal performance of their vehicles. With its ability to efficiently deliver fuel, regulated by the fuel pressure regulator, the fuel pump ensures a consistent flow of fuel to the engine, enabling smooth and reliable operation.

HOW TO CHOOSE A FUEL PUMP?

Fuel pumps are available in a variety of shapes, sizes, and with different features. Several factors come into play when selecting a fuel pump, but the most significant determining factors include the engine's fuel efficiency, horsepower, voltage, and maximum fuel system pressure.

1. Engine Fuel Efficiency:

The fuel efficiency of an engine refers to the amount of fuel required to produce 1 horsepower (HP) for 60 minutes. This measurement is commonly known as the engine's Brake Specific Fuel Consumption (BSFC). Modern engines can be categorized into three broad types based on their BSFC rating:

- Normal Aspirated Engine: Industry B.S.F.C Standards: 0.45 – 0.5

- Supercharged engines (nitrous combinations): Industry B.S.F.C Standards: 0.55 – 0.60

- Turbocharged engines (forced induction): Industry B.S.F.C Standards: 0.6 – 0.65

Please note that these figures serve as general guidelines, and it is essential for vehicle owners to determine the exact BSFC of their engine by conducting an engine dyno test.

2. Fuel Volume:

The fuel volume required by a engine depends on its horsepower rating and BSFC. To calculate the average fuel requirement, multiply these two values. For example, let's consider a 650 HP engine with a .45 BSFC. The amount of fuel required would be 650 multiplied by .45, which equals 292 lbs of fuel.

It is worth noting that the more efficient the engine, the higher the BSFC and consequently, the greater the amount of fuel required. When shopping for an electric fuel pump, it is advisable to err on the side of caution and choose a pump that can deliver slightly more fuel than the engine actually needs. If you are unsure about your engine's horsepower rating, it is recommended to consult with an experienced mechanic. Making calculations based on inaccurate horsepower estimates can lead to significant engine damage.

3. Voltage:

Modern electric fuel pump systems rely on electricity to function. Fuel injectors are designed to operate within specific voltage limits. Therefore, when selecting a fuel pump, it is crucial to choose one that is compatible with the voltage output of your engine. For instance, attaching a fuel pump designed to work with 12 volts to a vehicle that outputs 13.5 volts can increase the volume of fuel being pumped by as much as 40 percent. This can quickly lead to pump issues. Additionally, excessive voltage can also impact the fuel pump relay.

By considering these essential factors - engine fuel efficiency, fuel volume, and voltage - you can make an informed decision when choosing a fuel pump that will best suit your vehicle's needs. Remember, selecting the right fuel pump is vital for optimal engine performance and reliability.

Popular Fuel Pumps

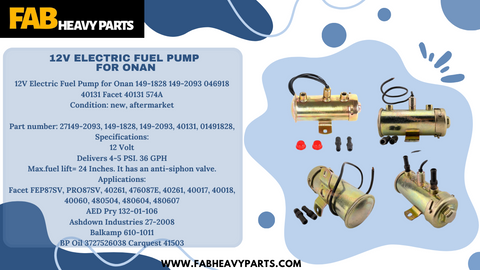

1. 12V Electric Fuel Pump for Onan

12V Electric Fuel Pump for Onan 149-1828 149-2093 046918 40131 Facet 40131 574A

Condition: new, aftermarket

Part number: 27149-2093, 149-1828, 149-2093, 40131, 01491828,

Specifications:12 Volt

Delivers 4-5 PSI. 36 GPH

Max.fuel lift= 24 Inches. It has an anti-siphon valve.

Applications:

Facet FEP87SV, PRO87SV, 40261, 476087E, 40261, 40017, 40018, 40060, 480504, 480604, 480607

AED Pry 132-01-106

Ashdown Industries 27-2008

Balkamp 610-1011

BP Oil 3727526038 Carquest 41503

Carrier Transicold 133395, 30-00106-00, 30-01007

Case New Holland T41054, D8NN-9350-BB

Caterpillar 91864-02800, 56ZE7424

Cummins (Onan) 0149-0554, 149-554, 149P554

2. New Fuel Pump for CAT Caterpillar

New Filter Fuel Pump 349-5327 3495327 for CAT Caterpillar 236B3 242B3 246C 252B3 256C

Part number: 349-5327, 3495327

Condition: new, aftermarket

Warranty 6 months

Compatible equipment models: 3495327:

COMPACT TRACK LOADER 259B3 279C 279C2 289C 289C2 299C

MULTI TERRAIN LOADER 257B3 277C 277C2 287C 287C2 297C

SKID STEER LOADER 236B3 242B3 246C 252B3 256C 262C 262C2 272C Caterpillar

3. New Fuel Pumpor for John Deere

New Fuel Pump RE27667 RE527115 RE42211 RE37482 for John Deere 310 310A 310C 315C 401C

Condition: new, aftermarket

Part number: RE27667 RE527115 RE42211 RE37482

Application:

BACKHOE, LOADER 310 310A 310C 315C 401C 410 410B 410C 510B 610B 710B

BULLDOZER 450D 450E 450G 550A 550B 750B

EXCAVATOR 180 690D 750

FELLER BUNCHER 643 643D

FORKLIFT 480C

GRADER, MOTOR 570 570B 670 670A 670B

LOADER, CRAWLER 350B 450B 450C 455D 455E 555 555A 555B 655 655B 755 755A 755B

LOADER, FOUR-WHEEL DRIVE 344E 444 444C 444D 444E 544B 544C 544D 544E 644A

LOADER, TWO-WHEEL DRIVE 300B 302A

SCRAPER, ELEVATING 760

SIDEBOOM 300

SKIDDER, LOG 340D 350 440C 440D 450 540B 540D 550 640 640D

SLASH BUNDLER 380

TRACTOR 301 301A 302 401B 401D 760A

TRUCK, ARTICULATED DUMP 350C 350D Deere

4. Fuel Pump 6680503 6672427 for Bobcat

Fuel Pump 6680503 6672427 for Bobcat B100 B200 B250 BL275 E25 E26 463 553 S100 S70 Skid Steer Loader

Condition: new, aftermarket

Part number: 6680503, 6672427

Application: Bobcat B100 B200 B250 BL275 E25 E26 463 553 S100 S70 Skid Steer Loader

FAB Heavy Parts Can Help With Your Needs

Welcome to Fab Heavy Parts' online catalog, where you can explore a delightful array of Fuel Pumps. We have a diverse selection to cater to your needs. Our knowledgeable parts team is at your disposal, ready to assist you every step of the way.